Fire-safe building materials are essential components in modern construction, ensuring that structures can withstand and slow down the spread of flames. These materials—such as fire-rated gypsum boards and fire-resistant panels—not only protect lives but also reduce property damage during fire events. Choosing the right fire-safe materials and implementing smart design strategies are key to achieving optimal fire safety in buildings.

In today’s world, where urban density and high-rise developments are increasing rapidly, the importance of fire safety in construction cannot be overstated. Every year, thousands of buildings around the world suffer devastating losses due to fire-related incidents—many of which could have been prevented or minimized with proper planning and the use of fire-safe building materials.

Fire safety is no longer just a regulation or compliance requirement. It’s a core part of responsible architecture and construction strategy. Whether you’re an architect, engineer, project manager, or property developer, understanding how to choose materials that resist fire, how to interpret fire ratings like gypsum board fire rating, and how to design spaces that slow down flame propagation can save lives—and millions in damages.

In this article, we will explore the most effective strategies and technologies for making a building truly fire-safe, from selecting fire-resistant panels to navigating international certifications like NFPA and ASTM. Let’s dive in.

Understanding Fire-Safe Building Materials

Choosing the right fire-safe building materials is the foundation of any fire-resilient architectural plan. These materials are engineered to either resist ignition, prevent the spread of flames, or maintain structural integrity for a longer period during a fire. Their use has become not just a safety precaution but a fundamental requirement in many international building codes.

There are three main types of materials used in fire-safe construction:

🔹 Non-Combustible Materials

These materials do not ignite, burn, or release flammable vapors. Examples include concrete, brick, steel, and fire-resistant panels made from inorganic compounds. They’re ideal for core structural components like walls, columns, and floors.

🔹 Fire-Retardant-Treated Materials

These are typically organic materials (such as wood or fabrics) that have been chemically treated to delay ignition. While not as resilient as non-combustibles, they are used when aesthetics or cost requires flexible material choices.

🔹 Fire-Rated Assemblies

Fire-rated systems combine several components—walls, doors, ceilings—tested together to resist fire for a certain duration (e.g., 60 minutes, 120 minutes). Products like gypsum boards with fire ratings play a key role in these assemblies, offering both passive resistance and code compliance.

Fire-safe building materials not only improve safety but also contribute to longer evacuation times, better fire compartmentalization, and reduced insurance premiums. When selecting materials, it’s crucial to look beyond the label—consider fire test certifications, performance data, and suitability for your specific project environment.

Types of Fire-Resistant Panels Used in Construction

Fire-resistant panels are an essential subset of fire-safe materials, designed to act as barriers against flame spread and to retain structural integrity during extreme heat. These panels are widely used in both residential and commercial construction to meet safety standards and reduce the risk of fire-related disasters.

Here are the most commonly used types of fire-resistant panels in modern buildings:

🔸 Fire-Rated Gypsum Boards

Also known as Type X or Type C drywall, these panels are reinforced with fiberglass and other additives that improve fire resistance. A standard gypsum board fire rating might range from 30 minutes to 2 hours, depending on thickness and assembly. Fire-rated gypsum is ideal for interior partitions, ceilings, and shaft walls.

🔸 Cement Boards

Made from cement and fiberglass mesh, these panels are non-combustible and moisture-resistant. Although heavier and harder to work with, they are perfect for exterior facades, wet areas, and fire-rated assemblies in commercial construction.

🔸 MGO (Magnesium Oxide) Boards

These high-performance panels offer excellent fire resistance, mold protection, and structural strength. They’re gaining popularity as eco-friendly alternatives to traditional boards, especially in green buildings or projects pursuing LEED certification.

🔸 Fiber Cement Panels

Composed of cement, sand, and cellulose fibers, these panels are used in cladding and roofing due to their strong fire, moisture, and pest resistance. They are durable and aesthetically flexible, making them suitable for modern designs.

Each of these fire-resistant panels has distinct advantages depending on the application. For instance, while gypsum board fire ratings are ideal for interior walls, MGO boards are better suited for environments requiring both fire and mold resistance. The key to effective fire-safe construction lies in choosing the right panel based on exposure risk, building code requirements, and environmental conditions.

Fire Ratings Explained: What Is Gypsum Board Fire Rating?

Understanding the concept of gypsum board fire rating is crucial for architects, contractors, and project managers who aim to build fire-resilient structures. Fire ratings determine how long a material or assembly can resist fire under standardized test conditions, typically expressed in minutes (e.g., 30, 60, 90, 120).

🔸 What Is a Fire Rating?

A fire rating is the amount of time a building material or system can withstand exposure to fire without failing structurally or allowing flames and heat to pass through. It’s not just about the material alone, but the performance of the entire assembly (e.g., wall studs, insulation, panels, fasteners).

🔸 Fire Rating of Gypsum Boards

Fire-rated gypsum boards, such as Type X and Type C, are specifically formulated to resist fire for longer periods compared to standard drywall. These panels typically include non-combustible glass fibers and other additives that slow down heat penetration and core disintegration.

- Type X: Offers 60-minute fire resistance when installed properly.

- Type C: Contains more glass fibers and expands when heated, filling gaps and maintaining integrity up to 120 minutes in multi-layer assemblies.

These boards are tested according to ASTM E119 (North America) or EN 1364-1 (Europe), simulating real-world fire conditions. The gypsum board fire rating is often required by local building codes for stairwells, corridors, elevators, and partition walls between residential units.

🔸 Factors That Affect Fire Rating

- Thickness of the board: Thicker boards offer better resistance.

- Number of layers: Double-layer assemblies provide enhanced protection.

- Installation method: Gaps, joint treatments, and screw spacing all influence performance.

Choosing a board with a certified fire rating ensures your project complies with safety regulations and provides peace of mind in case of emergency.

Design Strategies for Enhancing Fire Resistance

Selecting fire-safe building materials is only one part of the equation. For a structure to be truly fire-resilient, thoughtful design strategies must also be integrated into the architectural and engineering plans. These strategies work in tandem with fire-resistant panels and rated assemblies to reduce fire spread, protect occupants, and support safe evacuation.

🔸 Compartmentalization

Fire compartmentalization involves dividing a building into fire-resistive zones using walls, ceilings, and floors that can contain a fire for a defined period. Installing fire-rated gypsum boards and other fire-resistant panels in these zones slows the spread of flames and smoke, giving people more time to escape and firefighters more time to respond.

🔸 Passive Fire Protection

Unlike active systems (sprinklers, alarms), passive fire protection (PFP) involves building components that prevent the spread of fire without requiring human or mechanical activation. Examples include fire doors, intumescent seals, and the strategic use of fire-safe building materials like MGO boards and cement-based panels.

🔸 Egress Design

Proper egress routes—hallways, stairwells, and exit paths—must be constructed using materials with high gypsum board fire rating to maintain structural integrity during fire. These paths should also remain free of combustible finishes and have clearly marked exits.

🔸 Fire-Stopping and Sealing

Fire can travel through penetrations in walls and floors created by pipes, ducts, or cables. Designers must incorporate fire-stopping materials that expand under heat to block these gaps. Coordination between mechanical and architectural teams is crucial here.

🔸 Ventilation Control

Airflow management can dramatically affect how smoke and fire move through a building. Smart HVAC zoning, smoke barriers, and automatic dampers help contain fire within a controlled zone, especially when combined with fire-resistant panels.

Integrating these design strategies not only enhances life safety but may also reduce insurance premiums and facilitate easier code approval. It also demonstrates a forward-thinking approach to risk mitigation in high-density or high-risk environments.

Certifications & Compliance for Fire-Safe Buildings (NFPA, ASTM, etc.)

Fire safety in buildings is governed by a complex framework of international standards and certifications that ensure fire-safe building materials perform reliably under emergency conditions. These certifications are not optional; they are often mandatory for building permits, insurance coverage, and public safety compliance.

🔸 NFPA (National Fire Protection Association)

NFPA develops and publishes codes that are widely adopted worldwide. One of the most important is NFPA 5000, which outlines minimum design and construction requirements for fire-safe structures. It emphasizes the use of fire-resistant panels and rated assemblies in structural components, especially in high-rise and commercial buildings.

🔸 ASTM International

ASTM provides testing standards for fire performance. ASTM E119, for example, is used to determine how long materials like gypsum boards can withstand fire. This test measures flame spread, temperature rise, and structural failure points, forming the basis for assigning gypsum board fire ratings.

🔸 UL (Underwriters Laboratories)

UL conducts safety testing for building materials, including fire-resistance classification. Products that bear the UL mark have passed rigorous tests and can be trusted for use in safety-critical applications. UL-listed fire-rated gypsum boards are common in healthcare, education, and transport infrastructure.

🔸 EN Standards (Europe)

European fire safety codes like EN 1364-1 assess wall and ceiling systems’ resistance to fire and smoke. These standards are essential for international construction projects and align closely with sustainable building initiatives.

🔸 Local Building Codes

Many countries adopt NFPA or ASTM standards with minor modifications. Understanding and complying with local regulations is vital, especially in jurisdictions with strict safety mandates (e.g., UAE, Qatar, Saudi Arabia).

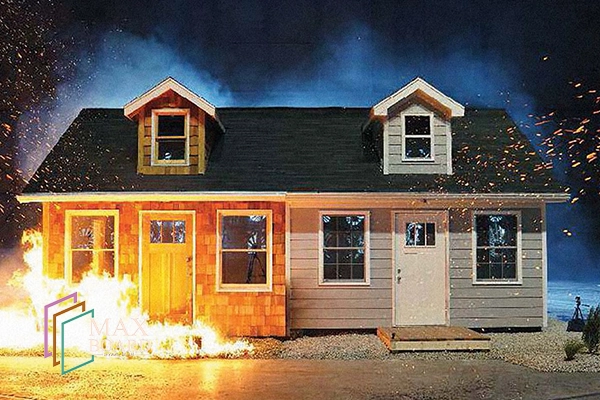

Case Study: High-Risk Buildings & Lessons Learned

The consequences of ignoring fire-safe building materials can be catastrophic. Real-world case studies highlight how poor material choices and inadequate design strategies lead to loss of life, structural collapse, and massive financial damage. These lessons are crucial for industry professionals committed to safety and resilience.

🔸 Grenfell Tower Fire (London, 2017)

One of the most tragic examples in recent history, the Grenfell Tower fire resulted in 72 fatalities and global outrage. Investigations revealed that the cladding material used was highly flammable, and the building lacked proper fire compartmentalization. If fire-resistant panels and non-combustible insulation had been used, the fire might have been contained.

🔸 Address Downtown Fire (Dubai, 2015)

This high-rise hotel caught fire on New Year’s Eve due to an electrical short circuit. While no lives were lost, extensive damage occurred. A post-incident report emphasized the need for stricter compliance with international standards like NFPA 5000 and use of certified gypsum boards with fire rating in interior assemblies.

🔸 Brazil Museum Fire (Rio, 2018)

The National Museum in Brazil was engulfed in flames, resulting in the loss of over 20 million artifacts. Lack of sprinkler systems and non-fire-rated materials contributed to the spread. A combination of fire-safe building materials and early fire detection systems could have preserved this cultural treasure.

Key Lessons:

- Fire-resistance is not a luxury—it’s a necessity.

- Using uncertified or combustible materials increases risk exponentially.

- Compliance with ASTM, NFPA, and other standards can save lives and investments.

- Material choices like fire-rated gypsum boards and MGO panels are essential for high-risk zones.

Why Fire-Safe Materials Are Also Sustainable

There’s a common misconception that fire-safe building materials and eco-friendly design are mutually exclusive. In fact, many fire-resistant panels contribute directly to sustainable construction by improving building durability, energy efficiency, and long-term environmental performance.

🔸 Durability Equals Sustainability

Materials like fire-rated gypsum boards and MGO panels extend a building’s lifespan by resisting fire, mold, and decay. This means fewer replacements, less waste, and lower environmental impact over time. A longer-lasting structure reduces the need for demolition and reconstruction—two major sources of carbon emissions in construction.

🔸 Energy Efficiency

Many fire-resistant materials have excellent thermal insulation properties. MGO boards, for instance, not only resist fire but also help stabilize indoor temperatures, reducing HVAC energy consumption. This dual benefit is especially valuable in green building certifications like LEED and BREEAM.

🔸 Indoor Air Quality

Certified fire-safe building materials are tested not just for fire resistance, but also for emissions. Low-VOC or zero-VOC ratings mean healthier indoor air, especially in schools, hospitals, and homes. Fire-resistant materials are often non-toxic, making them ideal for sensitive environments.

🔸 Recyclability and Low Embodied Energy

Products such as fiber cement and MGO panels are increasingly being produced using recycled content or renewable inputs. Their manufacture consumes less water and energy than traditional construction materials like steel or concrete.

🔸 Compliance with Green Building Standards

Materials with proven gypsum board fire ratings often qualify for points under sustainability programs. LEED, WELL, and Estidama all recognize fire-resilient construction as a key component of building performance and occupant safety.

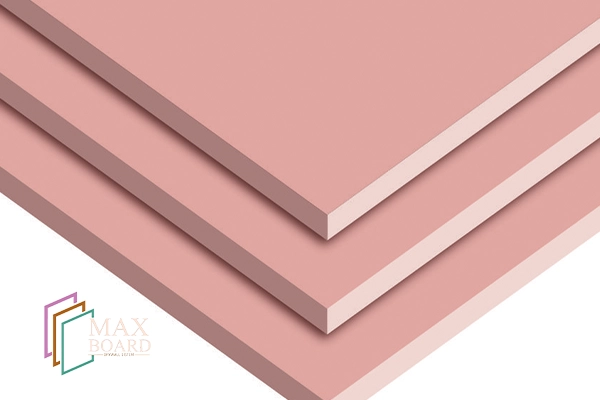

Our Recommendation: Fire-Rated Gypsum Boards by MaxBoard

When it comes to selecting fire-safe building materials, not all products are created equal. That’s why we confidently recommend the Fire-Rated Gypsum Boards by MaxBoard—a high-performance solution trusted by engineers, architects, and contractors across residential, commercial, and industrial projects.

🔸 Certified Fire Resistance

MaxBoard’s fire-rated gypsum boards have been rigorously tested under ASTM E119 and EN 1364-1 standards, achieving superior gypsum board fire ratings up to 120 minutes. This makes them ideal for fire-rated walls, ceilings, stairwells, and corridor assemblies.

🔸 Strength & Stability

Thanks to reinforced fiberglass cores and precision-engineered density, these boards maintain structural integrity even under extreme temperatures. They don’t crack, warp, or collapse prematurely—ensuring safety in critical building zones.

🔸 Moisture & Mold Resistant

Unlike traditional gypsum boards, MaxBoard fire-rated products are also resistant to moisture and mold, reducing the risk of hidden hazards that compromise safety over time. This dual resistance makes them especially effective in high-humidity or mixed-use environments.

🔸 Easy to Install

With lightweight panels, standard cutting tools, and straightforward joint finishing, MaxBoard fire-rated gypsum boards offer speed and flexibility on-site. That means lower labor costs and fewer construction delays.

🔸 Sustainable Manufacturing

MaxBoard uses low-VOC binders and energy-efficient processes in its production facilities. Our fire-rated boards are recyclable and contribute to LEED and Estidama points in green construction projects—combining safety with sustainability.

📦 Available Specifications:

- Sizes: 1200 × 2400 mm / 1220 × 2440 mm

- Thickness: 12.5 mm / 15 mm

- Core: Fire-resistant fiberglass reinforced

- Compliance: ASTM E119, NFPA 5000, EN 1364-1

- Applications: Partitions, shafts, ceilings, egress corridors

Why Choose MaxBoard?

If you’re seeking a reliable, tested, and eco-conscious solution for fire-safe construction, MaxBoard’s fire-rated gypsum boards deliver on every front—protection, durability, and performance.

Get Expert Advice & a Custom Quote

Looking to integrate fire-safe building materials into your next project? Whether you’re planning a commercial high-rise, an industrial facility, or a residential compound, MaxBoard’s fire-rated gypsum boards offer industry-leading protection, performance, and peace of mind.

💡 Our team of experts is ready to assist you with:

- Product selection based on your local fire codes

- Technical specifications and installation guides

- Bulk pricing and delivery options

- Compliance documentation (ASTM, EN, NFPA)

📝 Fill out the form to request a quote or schedule a consultation.

We’ll get back to you with all the details tailored to your project’s location, scope, and needs.

Your safety is not just a feature. It’s our promise.