Moisture-resistant gypsum panels are specially engineered to prevent mold, warping, and structural degradation in high-humidity environments. Their water-repellent core and protective surfacing make them ideal for use in bathrooms, kitchens, coastal buildings, and tropical climates. This article explains how they work and why they outperform standard gypsum boards in humid conditions.

Introduction:

Humidity can be a silent destroyer in building environments. From warping walls to spreading mold, excessive moisture can compromise both the aesthetics and structural integrity of a building—especially in regions with tropical weather, coastal exposure, or poor ventilation. That’s why choosing the right interior wall and ceiling materials is critical for long-term durability.

One of the most reliable solutions for humid conditions is moisture-resistant gypsum panels. These specially designed boards offer superior resistance to moisture penetration compared to standard drywall. Whether it’s a hotel in a coastal city, a bathroom in a residential tower, or a hospital in a tropical region, these panels help preserve indoor surfaces, reduce maintenance costs, and improve indoor air quality.

In this article, we will explore what makes moisture-resistant gypsum panels unique, how they function in humid environments, and how to install them properly for maximum performance.

What Are Moisture-Resistant Gypsum Panels?

Moisture-resistant gypsum panels—often referred to as green boards or MR boards—are a specialized type of drywall engineered to withstand high humidity and occasional moisture exposure. Unlike standard gypsum boards, these panels feature a core that is chemically treated with water-repellent additives and are typically encased in a mold-resistant, moisture-resistant paper or fiberglass mat.

Key Components:

- Gypsum core: Same as regular drywall, but with added hydrophobic (water-repelling) chemicals.

- Surface facing: Usually green-colored paper or a fiberglass layer treated to resist mold and mildew.

- Edge coating: Sealed edges to prevent moisture absorption through vulnerable points.

Typical Applications:

- Bathrooms and powder rooms

- Kitchens and utility rooms

- Basements and laundry areas

- Commercial settings: healthcare facilities, schools, and public restrooms

- Buildings in tropical and coastal climates

While they’re not designed for direct water contact (like showers or exteriors), moisture-resistant gypsum panels are ideal for areas where elevated humidity is persistent. Their role is to serve as a durable, low-risk alternative to regular gypsum boards that may degrade under similar conditions.

How Humidity Damages Standard Building Materials

Humidity is one of the most common yet underestimated threats to buildings, especially in tropical, coastal, and poorly ventilated environments. Over time, constant exposure to moisture can silently deteriorate both structural and non-structural components, leading to costly repairs and health hazards.

Standard gypsum boards, which are made with untreated paper facings and cores, are particularly vulnerable to high humidity. When exposed to moisture:

- The paper surface can absorb water, leading to bubbling, peeling, or discoloration.

- The gypsum core may soften or crumble, weakening the wall’s integrity.

- Prolonged exposure can promote the growth of mold, mildew, and fungi, posing health risks to occupants.

- Moist walls can attract termites or other pests, particularly in wooden structures.

In severe cases, walls made of standard gypsum boards may need complete replacement due to rot or contamination. That’s why builders in humid regions are increasingly shifting toward moisture-resistant gypsum panels, which offer an extra layer of defense against moisture-related damage.

This shift is not only about durability but also about creating a healthier indoor environment, free from the risks of mold-related illnesses and structural failure.

How Moisture-Resistant Gypsum Panels Work

The effectiveness of moisture-resistant gypsum panels lies in their specially engineered structure, which is designed to minimize water absorption and prevent internal degradation. These panels are not waterproof, but they offer a significantly higher level of resistance to humidity and incidental moisture than standard gypsum boards.

How They Function:

Moisture-resistant gypsum panels use a combination of features to enhance performance:

- Hydrophobic core treatment

The gypsum core is infused with silicone or other water-repellent compounds. This modification reduces the material’s porosity and prevents water from being absorbed into the core, even under high humidity. - Moisture-resistant facings

The surface is typically covered with specially treated paper or fiberglass mats that resist mold, mildew, and fungus growth. Unlike standard paper, this layer does not retain moisture and dries quickly. - Edge sealing and durability

The edges of the panels are often sealed to prevent moisture ingress at vulnerable joints. This helps maintain the panel’s structural integrity and reduces the risk of swelling or separation at seams. - Compatibility with mold-resistant finishing systems

When used with mold-resistant joint compounds, sealants, and paints, moisture-resistant gypsum panels form a complete moisture-control system suitable for long-term performance in wet-prone areas.

These design features collectively provide a barrier against the most common forms of water damage, extending the life of the wall system and improving the overall resilience of the building.

Benefits in Residential and Commercial Buildings

The use of moisture-resistant gypsum panels offers a wide range of benefits for both residential and commercial construction, particularly in spaces where humidity and moisture exposure are persistent concerns. From private homes to high-traffic public facilities, these panels contribute to both durability and indoor air quality.

In Residential Buildings:

- Bathrooms and powder rooms

Areas with frequent steam, splashing, or water vapor benefit significantly from the moisture resistance of these panels. - Kitchens and laundry rooms

Regular cooking, washing, and high indoor humidity levels can degrade standard drywall, making moisture-resistant panels a more reliable choice. - Basements and crawlspaces

These lower-level spaces are prone to dampness and water intrusion, requiring wall systems that won’t deteriorate quickly.

In Commercial and Institutional Settings:

- Hospitals and clinics

Cleanliness, hygiene, and mold prevention are critical in healthcare environments. Moisture-resistant panels help maintain sterile conditions. - Schools and universities

Buildings with high occupancy and fluctuating environmental conditions benefit from durable, low-maintenance materials. - Hotels, gyms, and spas

In hospitality and wellness facilities where bathrooms, pools, and steam rooms are present, wall panels must perform under constant exposure to moisture and condensation. - Offices in coastal or tropical regions

High humidity levels and salt-laden air can quickly deteriorate untreated materials. Moisture-resistant panels provide longevity and protection.

In all these cases, moisture-resistant gypsum panels help reduce maintenance costs, extend the life of interior finishes, and support a healthier indoor environment.

Comparison: Moisture-Resistant vs. Regular Gypsum Panels

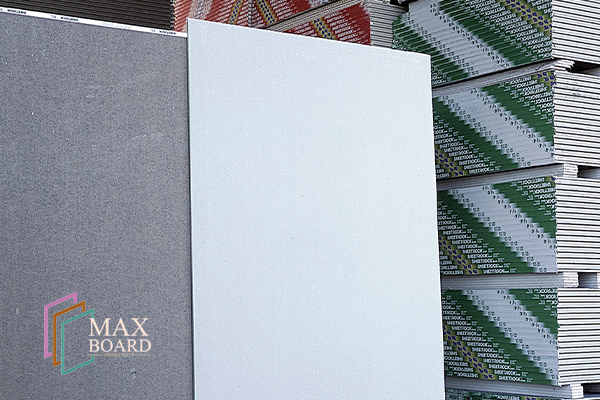

When choosing wall panels for humid environments, understanding the differences between moisture-resistant gypsum panels and regular gypsum boards is essential. Though they may appear similar at first glance, their performance under moisture exposure varies significantly.

Core Differences:

1. Core Composition

- Moisture-resistant gypsum panels: Treated with hydrophobic agents to repel moisture.

- Regular gypsum boards: Untreated core, highly absorbent and prone to degradation when exposed to humidity.

2. Surface Facing

- Moisture-resistant: Covered with moisture-resistant paper or fiberglass mats.

- Regular: Standard paper facing that can retain water and foster mold growth.

3. Mold Resistance

- Moisture-resistant: Inhibits mold and mildew when combined with proper installation.

- Regular: Offers no protection against microbial growth.

4. Durability in Wet Areas

- Moisture-resistant: Suitable for kitchens, bathrooms, and basements.

- Regular: Not recommended for any high-moisture area.

5. Cost

- Moisture-resistant: Slightly more expensive due to added treatments and performance features.

- Regular: Lower initial cost but may lead to higher maintenance or replacement expenses.

Conclusion of Comparison:

While regular gypsum boards are suitable for dry interior spaces, they are ill-suited for moisture-prone environments. In contrast, moisture-resistant gypsum panels offer a safer, longer-lasting solution with better value over time in humid climates.

Installation Best Practices in Humid Environments

Even the best materials can fail if not installed correctly. To ensure the long-term performance of moisture-resistant gypsum panels, it’s important to follow proper installation practices tailored for humid or high-moisture environments. These practices help prevent hidden weaknesses that may lead to moisture intrusion, mold growth, or panel failure.

Key Installation Guidelines:

1. Use corrosion-resistant framing and fasteners

Metal studs and screws used in humid environments should be galvanized or coated to prevent rust, which can weaken connections over time.

2. Leave adequate spacing between panels

Allow for slight expansion and contraction by maintaining a 1/8-inch gap between sheets. This prevents buckling due to humidity fluctuations.

3. Seal all joints with mold-resistant compounds

Joint treatment should include moisture- and mold-resistant tape and joint compound. Regular drywall compound can absorb moisture and compromise the system.

4. Apply waterproofing in critical areas

In bathrooms or laundry rooms, consider adding a waterproofing membrane or vapor barrier behind the moisture-resistant gypsum panels, especially around bathtubs, showers, or sinks.

5. Ensure proper ventilation

Even with moisture-resistant materials, ventilation is crucial. Install exhaust fans, dehumidifiers, or passive airflow systems to reduce long-term humidity buildup.

6. Avoid direct contact with water

These panels are designed to resist moisture—not to withstand soaking or direct water contact. Use cement boards or MGO panels in areas like shower walls or wet floors instead.

Final Tip:

Always follow manufacturer guidelines and local building codes for the specific product you’re using. Improper installation can void warranties and reduce the effectiveness of moisture-resistant gypsum panels.

Case Studies and Real-World Applications

To better understand the practical advantages of moisture-resistant gypsum panels, it’s helpful to look at how they’ve performed in real-world settings. Across both residential and commercial projects, these panels have proven to be an essential part of moisture management strategies—especially in challenging environments.

Residential Project: Coastal Villa in Southern Thailand

A luxury beachfront home in Krabi faced persistent humidity and salt-laden air. During renovations, standard gypsum boards in bathrooms and the kitchen had shown clear signs of swelling, peeling, and mold growth.

Solution:

Contractors replaced all interior wallboards in wet zones with moisture-resistant gypsum panels. After 18 months of monitoring, the panels showed no signs of warping or microbial damage, and indoor air quality improved significantly.

Commercial Project: Health Clinic in the UAE

In a government-funded clinic near the Gulf coast, internal humidity combined with continuous cleaning protocols caused issues with previous wall materials. Moisture infiltration was leading to bubbling paint and mildew buildup in patient rooms and restrooms.

Solution:

The facility opted for moisture-resistant gypsum panels throughout high-humidity zones. Maintenance reports six months post-installation showed a dramatic reduction in surface issues and zero mold-related incidents.

Educational Project: School Renovation in Malaysia

A public school in Kuala Lumpur needed durable interior wall solutions that could withstand daily cleaning, occasional flooding, and seasonal monsoons.

Result:

By switching to moisture-resistant gypsum panels in classrooms, hallways, and restrooms, the school reduced annual maintenance costs by 40% and extended the lifespan of wall finishes in critical areas.

These examples illustrate that moisture-resistant gypsum panels are not just a niche product, but a practical and high-performing choice for a wide variety of projects in humid or coastal regions.

Conclusion

Controlling moisture is one of the biggest challenges in construction, especially in environments where high humidity is constant. Using the wrong materials can lead to serious structural damage, costly repairs, and health risks due to mold and mildew. That’s why selecting appropriate interior wall materials is critical.

Moisture-resistant gypsum panels offer a simple yet powerful solution. Engineered with hydrophobic cores and mold-resistant facings, these panels significantly reduce the risk of moisture damage in bathrooms, kitchens, basements, and buildings located in tropical or coastal regions.

Their slightly higher upfront cost is quickly offset by long-term savings in maintenance and replacement, making them an ideal choice for both residential and commercial applications.

Whether you’re building from the ground up or renovating an existing space, moisture-resistant gypsum panels provide peace of mind and performance where it matters most.

Looking for reliable, high-performance wall panels for humid environments?

MaxBoard-MGO offers a full line of moisture-resistant gypsum panels manufactured to meet international quality standards. Designed for durability, mold resistance, and moisture protection, our panels are trusted by contractors and architects across tropical and coastal regions.

👉 Visit MaxBoard-MGO.com to explore our full product range or contact our team for project-specific recommendations.

Frequently Asked Questions (FAQs)

Are moisture-resistant gypsum panels waterproof?

No, moisture-resistant gypsum panels are not waterproof. They are designed to resist humidity and occasional moisture exposure but should not be used in areas with constant water contact, such as inside shower stalls or exterior walls.

Can I use moisture-resistant gypsum panels in kitchens and bathrooms?

Yes. These panels are ideal for kitchens, bathrooms, laundry rooms, and other interior spaces with high humidity. However, for wet areas with direct water contact (like behind showers), use cement boards or MGO panels instead.

Do moisture-resistant gypsum panels prevent mold?

They significantly reduce the likelihood of mold growth by resisting moisture absorption and using mold-inhibiting surface materials. However, proper installation and ventilation are also key to complete mold prevention.

Are they more expensive than regular drywall?

Yes, but only slightly. The higher upfront cost is usually justified by their longer lifespan, reduced maintenance, and better performance in humid environments.

Can I paint or tile over moisture-resistant gypsum panels?

Absolutely. These panels can be finished just like standard drywall—painted, tiled, or wallpapered—as long as compatible products are used and surfaces are properly primed and sealed.