The best panel for high-humidity environments combines water resistance, mold prevention, and structural durability. While standard drywall often fails in damp conditions, modern moisture-resistant building materials like MGO panels and MR gypsum boards offer superior performance. Experts recommend using these solutions in bathrooms, basements, and kitchens for long-term protection and indoor air quality.

Introduction: The Hidden Cost of Moisture in Construction

Moisture may seem harmless, but in the world of construction, it can silently destroy walls, floors, and even entire structural systems. In modern homes and commercial buildings, especially those located in coastal or humid regions, moisture infiltration is one of the leading causes of material degradation, mold outbreaks, and costly repairs.

Traditional materials, such as standard drywall, are highly vulnerable to humidity. They absorb moisture, lose strength, and often become breeding grounds for mold. This not only compromises the building’s durability but also poses health risks to its occupants.

To prevent such issues, architects and contractors are turning to smarter solutions—specifically, moisture-resistant building materials designed for long-term performance. Among them, selecting the right panel for high-humidity environments has become a critical factor in project planning. When chosen wisely, these materials can reduce maintenance costs, extend building lifespan, and significantly improve indoor air quality.

Why Humidity Is a Big Deal in Modern Building Projects

Humidity is no longer just a regional problem—it’s a global concern affecting residential, commercial, and industrial buildings alike. As climate change drives higher levels of atmospheric moisture, architects and builders must now account for humidity as a core factor in material selection and design.

High humidity levels can lead to:

- Mold and mildew growth on walls, ceilings, and behind finishes

- Compromised indoor air quality, which can affect respiratory health

- Warping and deterioration of standard drywall and wood-based materials

- Decreased insulation efficiency due to moisture penetration

- Costly repairs caused by hidden water damage and rot

In this context, choosing the right panel for high-humidity environments is no longer optional—it’s essential. That’s why many construction professionals are shifting toward moisture-resistant building materials such as fiber-cement panels and MGO panels, which maintain integrity in damp, humid conditions.

Common Problems in High-Humidity Areas (Bathrooms, Kitchens, Basements)

Spaces like bathrooms, kitchens, and basements are constantly exposed to high levels of humidity—whether from steam, cooking, water splashes, poor ventilation, or proximity to the ground. If not properly addressed during construction, these areas can quickly become zones of deterioration, health hazards, and ongoing repair expenses.

🔹 Bathrooms

Bathrooms are the most obvious culprits. Hot showers generate steam that lingers in the air and seeps into wall surfaces. Without proper moisture protection, standard drywall can:

- Absorb the humidity

- Bubble, warp, or sag

- Become a feeding ground for mold and mildew

- Lead to structural softening and paint damage

Using a high-quality panel for high-humidity environments, such as MGO panels or MR gypsum boards, can dramatically increase the bathroom’s resilience to steam and condensation.

🔹 Kitchens

Kitchens combine heat, steam, and splashing from sinks and appliances. This creates intermittent but persistent moisture exposure that can degrade walls over time. Areas around dishwashers, stovetops, and sinks are particularly vulnerable.

Moisture-resistant building materials in kitchen walls and backsplashes help prevent peeling paint, microbial growth, and wall damage—all while maintaining a clean, hygienic aesthetic.

🔹 Basements

Basements are naturally damp due to their below-grade positioning and contact with soil. Without vapor barriers and the right paneling, basements often suffer from:

- Musty odors

- Wall discoloration

- Mold spores circulating through the HVAC system

- Water stains and surface erosion

Installing MGO panels and other moisture-resistant building materials in basements reduces long-term damage and transforms them into livable, breathable spaces.

🔹 Bonus: Laundry Rooms & Utility Areas

Though often overlooked, laundry rooms and mechanical spaces experience high humidity from dryers, water heaters, and leaky plumbing. Using the wrong paneling in these spaces means guaranteed mold in the future.

What Makes a Panel Truly Moisture-Resistant?

Not all panels are created equal—especially when it comes to moisture performance. While some claim to be “water-resistant” or “mold-resistant,” only a few products on the market deliver true, long-term protection in high-humidity environments.

To be classified as a moisture-resistant building material, a panel must demonstrate three key capabilities:

1. Low Water Absorption Rate

A genuinely effective panel for high-humidity environments should absorb minimal moisture even after prolonged exposure. Panels with high porosity—like standard drywall—tend to wick water into the core, weakening the structure and creating a perfect breeding ground for mold. In contrast, MGO panels and MR gypsum boards are engineered with hydrophobic additives that drastically reduce water uptake.

✅ Performance Tip: Look for panels that meet or exceed standards like ASTM C1396 (for gypsum) or ASTM C1185 (for MGO).

2. Mold and Mildew Resistance

Moisture alone isn’t the only concern—what follows it is worse: mold. True moisture-resistant building materials incorporate antimicrobial coatings or non-organic compositions that resist fungal growth even in dark, humid spaces.

✅ MGO panels are naturally mold-resistant due to their inorganic magnesium oxide base. They contain no cellulose, which mold needs to grow.

3. Structural Integrity in Wet Conditions

Some panels may resist initial water damage but lose their shape or break down under extended exposure. A high-performance panel for high-humidity environments should maintain its dimensional stability—no warping, no sagging, no softening—over time.

✅ Moisture-resistant gypsum boards include reinforced glass fibers and treated paper facings to preserve rigidity.

✅ MGO panels, on the other hand, retain full structural performance in flood-prone or coastal regions—even after direct water contact.

4. Fire Resistance (Bonus Benefit)

Humidity and fire might seem unrelated, but high-humidity spaces—like mechanical rooms and kitchens—often involve heat, wiring, and flammable equipment. Some of the best moisture-resistant building materials, including MGO panels, are also fire-rated, making them ideal for dual-risk environments.

Comparing Common Panel Types: Standard Drywall, MR Gypsum, Cement, and MGO Panels

Choosing the right panel for high-humidity environments involves more than picking the cheapest or most available product. Each panel type has distinct characteristics that impact durability, resistance, cost, and long-term performance. Let’s break down the four most common options:

🟤 1. Standard Drywall (Regular Gypsum Board)

- Water Resistance: ❌ Very poor – absorbs moisture easily

- Mold Resistance: ❌ None – ideal breeding ground for mold

- Use Cases: Only for dry, interior spaces like bedrooms or hallways

- Lifespan in humid areas: Short – often requires replacement after minor exposure

- Verdict: Not recommended as a panel for high-humidity environments

🟢 2. MR Gypsum Boards (Moisture-Resistant Gypsum)

- Water Resistance: ✅ Improved – treated core resists moisture

- Mold Resistance: ✅ Good – antifungal additives in core and facings

- Use Cases: Bathrooms (non-wet walls), kitchens, laundry rooms

- Lifespan in humid areas: Medium – reliable with proper ventilation

- Cost: Slightly higher than standard drywall

- Verdict: A solid upgrade for light to moderate humidity protection

✅ Recognized as a dependable moisture-resistant building material.

⚪ 3. Cement Boards

- Water Resistance: ✅ Excellent – completely inorganic

- Mold Resistance: ✅ Excellent – mold can’t grow on cement

- Use Cases: Wet zones like inside showers, tub surrounds, outdoor applications

- Installation: Heavy, difficult to cut, requires specific tools

- Cost: Higher than gypsum boards

- Verdict: Ideal for direct water exposure, but not the most versatile solution for full wall systems

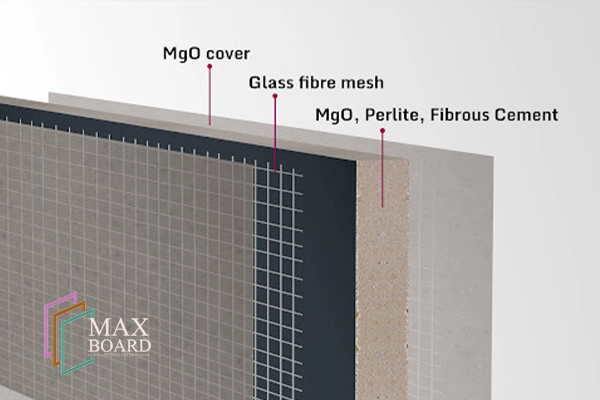

🔶 4. MGO Panels (Magnesium Oxide Boards)

- Water Resistance: ✅✅ Outstanding – minimal absorption, hydrophobic

- Mold Resistance: ✅✅ Naturally mold-proof – zero organic content

- Use Cases: Bathrooms, kitchens, basements, humid climates, flood-prone areas

- Fire Resistance: ✅ Class A-rated

- Installation: Similar to drywall, easier than cement board

- Sustainability: ✅ Low-VOC, recyclable, contributes to LEED

- Cost: Slightly higher than MR gypsum, but lower than cement boards

- Verdict: The most balanced, high-performance panel for high-humidity environments

✅ MGO panels are now the top recommendation from many industry professionals.

📊 Quick Comparison Table:

| Panel Type | Moisture Resistance | Mold Resistance | Fire Resistance | Installation Ease | Best Use Zone |

|---|---|---|---|---|---|

| Standard Drywall | ❌ Poor | ❌ None | ❌ Low | ✅ Easy | Dry interiors only |

| MR Gypsum Board | ✅ Good | ✅ Moderate | ✅ Basic | ✅ Easy | Humid interiors |

| Cement Board | ✅✅ Excellent | ✅✅ Excellent | ✅ High | ❌ Difficult | Wet zones |

| MGO Panel | ✅✅ Outstanding | ✅✅ Excellent | ✅✅ Class A | ✅ Easy | All humid zones |

The Verdict: Experts Prefer This Panel Type for Humid Zones

When it comes to long-term durability, health protection, and cost-efficiency, construction experts overwhelmingly recommend MGO panels as the ideal panel for high-humidity environments. These panels have proven to outperform traditional drywall, moisture-resistant gypsum boards, and even cement boards in most real-world scenarios.

Let’s explore why building professionals across the globe are making the switch:

✅ 1. Superior Moisture Control

Unlike gypsum-based or wood-composite materials, MGO panels are inorganic. This means they absorb almost no water, even when exposed to high humidity or direct contact. They remain stable, strong, and unaffected by moisture in environments like:

- Bathrooms with constant steam

- Kitchens with high cooking humidity

- Laundry rooms and utility areas

- Flood-prone basements

✅ 2. Built-In Mold Immunity

Because MGO panels contain no cellulose or organic fillers, mold has nothing to feed on. In independent lab tests, they consistently show zero fungal growth—even after prolonged exposure. This gives them a clear advantage over moisture-resistant building materials that still include paper facings or organic adhesives.

✅ 3. Easier Installation vs. Cement Boards

While cement boards offer similar moisture performance, they are heavy, brittle, and difficult to cut. MGO panels, by contrast, can be scored and snapped like gypsum, reducing labor time and tool wear.

✅ 4. Multi-Purpose Performance

In addition to moisture and mold resistance, MGO panels also offer:

- Fire resistance (Class A or EN 13501 A1-rated)

- Termite resistance (a bonus in warm or tropical climates)

- Sound insulation benefits in multi-family or office buildings

This combination of features makes them an all-in-one solution—not just a water-resistant panel, but a complete wall system upgrade.

✅ 5. Long-Term Cost Savings

Yes, MGO panels cost slightly more up front than MR gypsum. But the long-term ROI is clear:

- Fewer repairs and replacements

- No need for mold remediation

- Increased property value

- Lower insurance risk

Case Studies: Real-World Problems Solved by the Right Panel

Nothing illustrates the importance of using the right panel for high-humidity environments better than real-world examples. Builders and property managers around the world have faced costly damage due to poor material choices in moisture-prone spaces. Here’s how switching to moisture-resistant building materials, especially MGO panels, made a difference.

🏚️ Case Study 1: Mold Infestation in a Residential Basement (Florida, USA)

The Problem:

A newly finished basement began showing signs of mildew within six months. The walls, built with standard drywall, had absorbed ambient moisture. The musty odor spread throughout the home, and black mold appeared behind the paint.

The Solution:

The contractor replaced all affected drywall with MGO panels. Their low absorption and inorganic makeup eliminated future mold risks.

✅ Outcome: Air quality improved, no mold recurrence, and homeowner satisfaction restored.

🏨 Case Study 2: Hotel Bathrooms with Peeling Walls (Dubai, UAE)

The Problem:

A luxury hotel experienced constant maintenance requests for peeling paint and water-stained bathroom walls, even in newly renovated suites. Standard MR gypsum boards were used but couldn’t withstand daily steam exposure.

The Solution:

Engineers specified MGO panels for all bathroom walls and ceilings. These panels resisted steam, didn’t warp, and offered mold resistance without frequent repainting.

✅ Outcome: Reduced maintenance costs by 60%, improved guest satisfaction, and longer renovation lifecycle.

🏫 Case Study 3: School Kitchen with Repeated Wall Failures (Malaysia)

The Problem:

The school’s kitchen walls suffered repeated damage due to poor ventilation and high humidity from daily cooking. Cement boards used in the first renovation were too heavy and difficult to maintain.

The Solution:

MGO panels were installed due to their moisture resistance, fire rating, and ease of installation.

✅ Outcome: No maintenance issues after two years, faster installation, and improved kitchen hygiene certification.

Sustainability and Long-Term Cost Benefits

Beyond performance and protection, today’s construction materials must also align with sustainability goals and offer long-term financial value. MGO panels, as a top-tier panel for high-humidity environments, do both—reducing environmental impact while delivering serious cost savings over time.

🌱 1. Durability = Less Waste

Standard drywall and even MR gypsum boards often require replacement after several years in high-moisture spaces. This leads to:

- Construction waste

- Frequent labor costs

- Repeat material sourcing

MGO panels, on the other hand, last significantly longer—often outliving the surrounding structure. This durability leads to fewer replacements and less landfill contribution.

✅ Result: Lower environmental footprint + lower maintenance budget.

💧 2. Moisture Protection = Healthier Buildings

Long-term humidity exposure can lead to hidden mold outbreaks, which:

- Affect indoor air quality

- Cause respiratory issues

- Lead to costly remediation

Moisture-resistant building materials like MGO panels minimize these risks, creating healthier environments for families, workers, and students.

✅ Result: Reduced health-related costs and insurance claims.

🔥 3. Fire Safety + Moisture Resistance = Insurance Discounts

MGO panels combine Class A fire resistance with excellent moisture control. Many commercial and institutional buildings benefit from reduced insurance premiums by using such dual-protection materials.

✅ Result: Ongoing cost savings over the building’s lifetime.

🔁 4. Recyclable and Low-VOC

- MGO is manufactured using non-toxic, low-VOC binders.

- Panels are often recyclable depending on regional programs.

- Helps earn credits in LEED, BREEAM, and WELL certifications.

✅ Result: Easier compliance with green building standards and ESG policies.

🧮 5. Total Cost of Ownership

Let’s compare:

| Panel Type | Initial Cost | Replacement Cycle | Mold Risk | Lifecycle Cost |

|---|---|---|---|---|

| Standard Drywall | Low | 3–5 years | High | High |

| MR Gypsum Board | Medium | 5–8 years | Moderate | Medium |

| Cement Board | High | 10+ years | Low | High (labor) |

| MGO Panels | Medium+ | 20+ years | Very Low | Lowest |

✅ Over time, MGO panels emerge as the most cost-effective panel for high-humidity environments—balancing performance, sustainability, and affordability.

Why MaxBoard MR & MGO Panels Are Ideal for Moist Environments

When it comes to choosing the best panel for high-humidity environments, not all options on the market meet the standards of modern durability, health safety, and sustainability. That’s why MaxBoard has engineered two high-performance solutions that meet—and exceed—the demands of builders, architects, and developers around the world: our Moisture-Resistant Gypsum Boards (MR H3) and premium MGO panels.

🔹 MaxBoard MR H3 Gypsum Boards

- Designed for Interior Humid Zones: Ideal for kitchens, laundry rooms, and bathroom walls.

- Treated Core + Mold-Resistant Surface: Engineered to repel moisture and resist microbial growth.

- Easy Installation: Cuts and installs just like standard drywall, with added protection.

- Compliant with ASTM C1396 & EN 520 Type H1

✅ Use MaxBoard MR H3 when you need lightweight, budget-friendly, and reliable moisture-resistant building materials for residential interiors.

🔸 MaxBoard MGO Panels

- All-in-One Protection: Combines Class A fire resistance, zero mold growth, and ultra-low water absorption.

- Ideal for High-Risk Zones: Bathrooms, basements, kitchens, commercial kitchens, and utility rooms.

- Sustainable Manufacturing: Made with low-VOC materials and recyclable content.

- Certified Performance: Meets EN 13501-1, ISO 5660, ASTM C1185

✅ Use MaxBoard MGO panels when you need industrial-grade, high-performance, long-term protection in demanding environments.

Why Professionals Choose MaxBoard Panels

- Trusted by architects and contractors across residential, commercial, and institutional projects

- Backed by technical documentation, fire and moisture test results, and installation support

- Made for real-world durability—not just lab conditions

Ready to Build Smarter?

Our team at MaxBoard is ready to help you select the perfect panel for high-humidity environments—whether you’re working on a private home or a large-scale commercial site.

👉 Contact us now for a quote, technical guidance, or bulk order consultation.

Conclusion: Choose the Right Panel, Protect Your Project

Moisture is a silent destroyer in construction. It ruins walls, breeds mold, threatens health, and drives up maintenance costs. But with the right panel for high-humidity environments, you can turn these risks into lasting resilience.

From basements and bathrooms to commercial kitchens and laundry areas, the solution lies in advanced moisture-resistant building materials. And among them, MGO panels stand out as the most reliable choice for 2025 and beyond.

Whether you’re designing a smart home, renovating a hotel, or building in a tropical climate—don’t cut corners. Protect your investment with the strength, durability, and mold resistance that only MaxBoard panels can offer.

Take the First Step Toward Smarter, Safer Construction

👉 Browse our full range of moisture-resistant wall panels

👉 Learn more about the specs of MaxBoard MR H3 and MGO panels

👉 Contact our team for expert advice and pricing tailored to your project

Build for the future. Build with MaxBoard.