Wall panels for coastal buildings must be carefully selected to withstand high humidity, salt-laden air, wind-driven rain, and UV exposure. The ideal materials offer moisture resistance, corrosion durability, fire safety, and long-term structural integrity. This article explores the best wall panel options for coastal climates, helping architects and builders choose the most reliable and sustainable solutions.

Introduction:

Constructing buildings near coastlines comes with both opportunities and challenges. While ocean views and fresh air are desirable, the same coastal conditions can significantly accelerate material deterioration. From salt corrosion to mold growth, the environment puts constant stress on building components—especially wall assemblies, which act as the first line of defense.

That’s why choosing the right wall panels for coastal buildings is a decision that impacts not just appearance, but performance, safety, and lifespan. Poor material choices in these environments can lead to early failures, increased maintenance costs, and occupant discomfort.

In this comprehensive guide, we’ll break down the environmental risks unique to coastal zones and compare the best wall panel materials based on durability, moisture control, and resistance to salt, fire, and UV. Whether you’re designing a resort on the Gulf Coast or a residential complex near the Mediterranean, the right wall system makes all the difference.

Environmental Risks in Coastal Construction

Coastal regions pose a unique set of environmental challenges that directly impact material selection, especially when it comes to cladding and wall panels for coastal buildings. Unlike inland zones, structures built near oceans, seas, or large bodies of saltwater are constantly exposed to aggressive natural elements that can accelerate degradation and compromise building performance.

1. High Humidity and Constant Moisture

Humidity levels in coastal areas are persistently elevated due to proximity to large water masses. This creates an environment where moisture can penetrate wall systems, leading to warping, mold growth, and material breakdown over time. Standard wall panels without moisture-resistant cores or coatings often deteriorate within a few years.

2. Salt-Laden Air and Corrosion

The presence of salt in the air is one of the most damaging aspects of coastal climates. Salt particles are carried by the wind, settle on surfaces, and penetrate porous materials, leading to rust, corrosion, and chemical decay. This makes it essential to use wall panels for coastal buildings that offer high corrosion resistance and sealed surfaces.

3. Heavy Winds and Storm Exposure

Coastal zones are often subject to strong winds, storms, and even hurricanes. Wind-driven rain and pressure changes can test the strength of wall assemblies and their fasteners. Panels used in these areas must offer impact resistance and structural stability under extreme weather conditions.

4. UV Radiation and Thermal Expansion

Sunlight near the coast tends to be intense and prolonged. UV rays break down surface materials over time, while constant heating and cooling cause thermal expansion and contraction. These cycles can weaken wall finishes and loosen joints unless the selected materials are UV-stable and dimensionally stable.

5. Biological Growth and Air Quality Risks

Mold, mildew, algae, and bacteria thrive in humid environments. Inadequate wall panels allow moisture buildup behind facings, which can trigger microbial growth and compromise indoor air quality—a critical concern for schools, healthcare facilities, and hotels in coastal areas.

Understanding these risks is the first step toward selecting appropriate wall panels for coastal buildings that can endure harsh coastal elements while maintaining performance, appearance, and safety over time.

Key Performance Criteria for Coastal Wall Panels

Choosing reliable wall panels for coastal buildings requires more than just checking for water resistance. The best materials must meet a comprehensive set of performance criteria to ensure durability, safety, and low maintenance over time. Below are the key features to prioritize when selecting wall panel systems for use in coastal environments:

1. Moisture Resistance

The most essential characteristic of any wall panel used near water is its ability to resist moisture. Panels must have a low absorption rate and a core that remains stable even when exposed to high humidity or incidental water contact. Moisture-resistant cores reduce the risk of swelling, warping, and structural failure.

2. Mold and Mildew Prevention

Because coastal regions are often warm and humid, conditions are ideal for biological growth. Wall panels should be manufactured with anti-fungal additives or non-organic materials that do not support mold, mildew, or bacterial colonization.

3. Fire Resistance

Despite the humidity, fire safety is still a major consideration. Many coastal structures use flammable building materials elsewhere, and areas like kitchens or utility spaces require additional protection. Look for wall panels for coastal buildings with fire-resistant ratings that comply with local or international standards such as ASTM E84 or EN 13501-1.

4. Corrosion Resistance

Salt air accelerates oxidation in both fasteners and panel surfaces. The wall panel system—including framing, screws, joints, and coatings—should offer high resistance to corrosion to prevent staining, surface degradation, or long-term instability.

5. Structural Durability

Panels must be able to handle dynamic loads such as wind pressure, expansion and contraction cycles, and potential impacts from airborne debris. A robust structural profile, strong edge retention, and rigid core are essential.

6. Thermal and UV Stability

Temperature swings and prolonged sun exposure can weaken unprotected panels. The ideal wall panel should resist fading, cracking, or deformation caused by UV radiation and thermal cycling.

7. Sustainability and Certifications

Environmentally conscious builders should also consider whether the wall panel is LEED-compliant, VOC-free, and manufactured using recyclable or low-emission materials—especially for hotels, resorts, or public buildings promoting green design.

Meeting these criteria ensures that wall panels for coastal buildings not only survive but thrive under challenging environmental conditions—protecting both the structure and the people inside.

Common Types of Wall Panels Used in Coastal Areas

The market offers a wide range of wall cladding solutions, but only a few are truly suitable for coastal construction. When choosing wall panels for coastal buildings, it’s critical to evaluate how each material performs under the environmental stressors discussed earlier—moisture, salt, wind, and UV radiation.

Here’s a breakdown of the most commonly used wall panel types in coastal architecture, along with their advantages and limitations:

1. Magnesium Oxide (MGO) Boards

MGO boards are engineered to deliver excellent moisture resistance, fire performance, and mold protection. Their non-organic composition makes them ideal for high-humidity, salt-rich areas.

- ✅ Pros: Non-combustible, mold-resistant, low water absorption, dimensionally stable

- ⚠️ Cons: Slightly more expensive than basic gypsum

- 🌊 Best for: Coastal hotels, hospitals, marine facilities

2. Fiber Cement Boards

Made from cement reinforced with cellulose fibers, these panels are known for durability and resistance to fire and insects. They’re moderately resistant to moisture but can degrade over time if poorly installed.

- ✅ Pros: Tough, impact-resistant, non-combustible

- ⚠️ Cons: Heavier weight, may absorb moisture if unsealed

- 🌊 Best for: Exterior cladding in mid-rise buildings

3. Vinyl and PVC Cladding

Vinyl siding is lightweight and affordable. It offers some resistance to moisture and UV rays but lacks the rigidity and fire performance of other materials.

- ✅ Pros: Inexpensive, available in many finishes

- ⚠️ Cons: Can crack under impact, flammable

- 🌊 Best for: Budget residential buildings in mild coastal areas

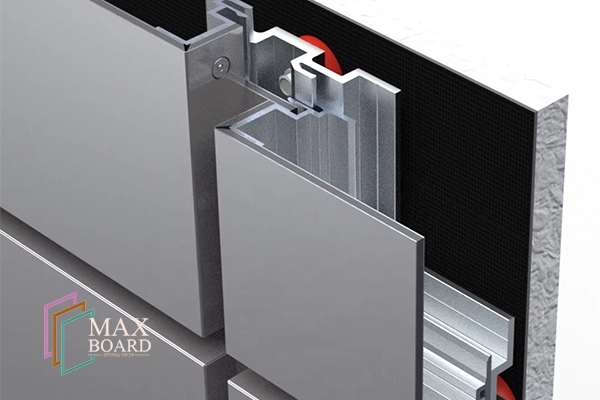

4. Aluminum Composite Panels (ACP)

ACP consists of two aluminum sheets bonded to a non-aluminum core. It’s widely used for its smooth finish and weather resistance.

- ✅ Pros: Lightweight, corrosion-resistant, sleek appearance

- ⚠️ Cons: Core may not be fire-rated (check specifications)

- 🌊 Best for: Coastal office buildings, facades

5. Stainless Steel Panels

Stainless steel cladding offers exceptional corrosion resistance and durability, but it comes at a premium price and may require special installation.

- ✅ Pros: Long lifespan, highly resistant to salt and moisture

- ⚠️ Cons: Expensive, industrial appearance

- 🌊 Best for: Coastal industrial or military structures

6. High-Density Gypsum Panels

Special formulations of gypsum panels with added moisture and mold inhibitors can work in limited coastal applications—usually interiors only.

- ✅ Pros: Fire-rated, easy to install

- ⚠️ Cons: Not suitable for high-humidity exteriors

- 🌊 Best for: Interior partitions in coastal hotels and homes

Understanding the properties of these materials allows builders to make informed choices when selecting wall panels for coastal buildings that align with project requirements, local climate, and long-term performance expectations.

Technical Comparison Table – Performance of Wall Panels in Coastal Conditions

When selecting wall panels for coastal buildings, it’s essential to move beyond marketing claims and analyze real-world performance. This section provides a side-by-side comparison of popular wall panel materials against key coastal challenges: moisture, salt corrosion, wind loads, fire risk, lifespan, and cost.

Comparative Table: Wall Panels vs Coastal Hazards

| Material Type | Moisture Resistance | Salt Corrosion | Wind Resistance | Fire Resistance | Lifespan | Cost Efficiency |

|---|---|---|---|---|---|---|

| MGO Board | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★★ | 30+ years | ★★★★☆ |

| Fiber Cement Board | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ | 25–30 years | ★★★☆☆ |

| Vinyl/PVC Cladding | ★★☆☆☆ | ★★☆☆☆ | ★★☆☆☆ | ★☆☆☆☆ | 10–15 years | ★★★★★ |

| Aluminum Composite | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★☆☆☆ | 20–25 years | ★★★☆☆ |

| Stainless Steel | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | 40+ years | ★★☆☆☆ |

| High-Density Gypsum | ★★☆☆☆ | ★★☆☆☆ | ★★☆☆☆ | ★★★★★ | 10–15 years | ★★★★☆ |

Key Takeaways:

- MGO boards provide the most balanced performance, excelling in all key areas while remaining cost-effective for medium to large-scale projects.

- Vinyl and PVC may be affordable, but they often fall short in long-term durability, fire safety, and resistance to salt.

- Stainless steel is unmatched in longevity and resilience, but its cost and aesthetics may not suit all building types.

This comparison helps architects and engineers make practical decisions when sourcing wall panels for coastal buildings—balancing performance, budget, and lifecycle considerations.

Why MGO Boards Are the Best Fit for Coastal Buildings

Among all the available options, MGO boards (Magnesium Oxide panels) consistently outperform traditional materials in coastal construction projects. Their engineered properties directly address the most critical challenges faced by buildings near the ocean—making them the top choice when specifying wall panels for coastal buildings.

1. Exceptional Moisture Resistance

Unlike wood-based or standard gypsum panels, MGO boards have a dense, non-organic core that repels moisture and maintains structural integrity in high-humidity environments. This makes them ideal for preventing warping, swelling, or softening due to prolonged exposure to coastal air.

2. Superior Mold and Mildew Protection

Because MGO contains no cellulose or organic fillers, it does not support the growth of mold, mildew, or fungi. This enhances both the indoor air quality and long-term health safety of coastal buildings—especially in sensitive spaces like hospitals or schools.

3. Inherent Fire Resistance

One of MGO’s most praised features is its naturally non-combustible composition. Certified to international standards like ASTM E136 and EN 13501-1, MGO boards offer a higher level of passive fire protection compared to vinyl, aluminum composite, or traditional gypsum.

4. Corrosion-Free and Inert

Salt-rich air can degrade many building materials over time. However, MGO panels are resistant to chemical breakdown, corrosion, or delamination—making them a highly stable solution in both interior and semi-exterior wall applications.

5. Impact Strength and Dimensional Stability

Thanks to their high compressive strength and low expansion coefficient, MGO boards maintain their shape and resist cracking under pressure from wind, fastener stress, or building movement—common in coastal zones.

6. Sustainability and LEED Contributions

MGO is an eco-friendly material often manufactured using low-carbon processes. It contains no toxic resins, is VOC-free, and can contribute to LEED credits in green-certified construction projects.

Real-World Application:

From coastal hospitals in the UAE to marine ports in Southeast Asia, wall panels for coastal buildings made from MGO are becoming the go-to choice for engineers and project managers seeking high-performance, code-compliant, and low-maintenance solutions.

Best Practices for Panel Installation in Coastal Projects

Even the highest-quality wall panels for coastal buildings can underperform if they’re not installed correctly. Harsh marine environments demand not only the right materials but also proper construction techniques that prevent moisture ingress, salt accumulation, and structural instability over time.

Here are the best practices that ensure wall panels perform as intended in coastal environments:

1. Use Corrosion-Resistant Fasteners

Standard steel screws or nails will quickly rust in salt-heavy air. For coastal projects, always use stainless steel, galvanized, or coated fasteners rated for marine-grade applications. This prevents premature panel loosening and staining.

2. Seal All Joints and Penetrations Properly

Unsealed joints are a major failure point in humid climates. Use high-performance, UV-resistant sealants to close all gaps, especially at panel seams, window frames, and utility penetrations. Expansion joints should also allow for thermal movement without cracking the finish.

3. Maintain Proper Ventilation and Drainage Behind Panels

Behind-wall airflow is essential in coastal zones. Use rainscreen systems or furring strips to create an air cavity that allows vapor to escape and prevents trapped moisture. Drainage mats can also direct water away from sheathing.

4. Protect Cut Edges and Screw Holes

Exposed edges and drilled holes can absorb water if not treated. Seal all cuts with a manufacturer-recommended primer or waterproofing coating. This step is particularly critical for fiber cement or gypsum-based boards.

5. Avoid Direct Ground Contact

Keep wall panels raised at least 6 inches (15 cm) above grade or pavement level. This prevents capillary water wicking and damage from splashback during storms or heavy rain.

6. Apply a Durable Exterior Coating

UV-stable paints, waterproof acrylic coatings, or elastomeric membranes can significantly extend the life of wall panels. These finishes reduce water absorption and resist fading, chalking, or peeling in harsh sunlight.

7. Follow Manufacturer Guidelines Strictly

Every wall panel product comes with specific installation instructions based on its chemistry and structure. Failing to follow these guidelines can void warranties and compromise the product’s coastal performance.

Following these best practices ensures that your selected wall panels for coastal buildings deliver the maximum return on investment—minimizing maintenance while maximizing structural safety and visual appeal.

Long-Term Maintenance & Care Tips

Proper maintenance plays a key role in extending the lifespan of wall panels for coastal buildings, even when top-quality materials like MGO or fiber cement are used. The salty, humid conditions in coastal zones accelerate material fatigue, which makes proactive care strategies critical.

Here are the most effective long-term maintenance tips to preserve both the function and appearance of coastal wall panel systems:

1. Schedule Routine Inspections

Inspect walls every 6–12 months for signs of corrosion, moisture intrusion, discoloration, or biological growth. Early detection helps prevent small issues from escalating into major repairs.

2. Clean Panel Surfaces Regularly

Salt deposits, algae, and dirt can build up over time. Use low-pressure water washing or mild, non-abrasive detergents to clean panels without damaging coatings or surfaces. Avoid harsh chemicals that may compromise panel integrity.

3. Re-seal Joints as Needed

Coastal environments cause faster sealant degradation. Check caulking at joints, windows, and penetrations annually, and reapply where necessary using UV- and marine-grade sealants.

4. Repaint or Recoat as Recommended

Exterior finishes fade over time, especially under intense UV. Follow the manufacturer’s recoating schedule—typically every 5 to 10 years—to maintain both protection and aesthetics. Use breathable coatings that don’t trap moisture inside.

5. Trim Nearby Vegetation

Plants growing too close to wall systems can trap moisture and promote mildew. Keep shrubs and vines trimmed away from wall surfaces to ensure airflow and sunlight exposure.

6. Monitor for Pest Activity

Some insects and birds are drawn to crevices in wall systems, especially in warm climates. Seal potential entry points and consider using non-toxic deterrents where applicable.

7. Check for Fastener Rust or Loosening

Over time, even corrosion-resistant screws may degrade. Inspect fasteners annually and replace any that show signs of rust, movement, or loss of grip.

By implementing these maintenance practices, building owners and facility managers can maximize the lifespan and performance of their wall panels for coastal buildings—ensuring continued structural protection, occupant safety, and minimal operational cost.

Coastal Building Codes & Compliance Considerations

When selecting and installing wall panels for coastal buildings, it’s not just about durability—compliance with local and international building codes is equally important. Coastal zones are often governed by stricter standards due to the elevated risk of wind, corrosion, flooding, and fire. Failure to meet these codes can result in fines, insurance issues, or compromised safety.

Here’s what to know about code requirements and regulatory compliance:

1. Wind Load Resistance Standards

Many coastal regions fall into high-wind zones or hurricane-prone areas. Wall panels must meet performance standards for wind uplift, impact resistance, and structural fastening. In the U.S., for example, products may need to comply with the Florida Building Code (FBC) or ICC-ES AC386 for panel performance.

2. Fire Safety Regulations

Fire-rated panels are often mandatory in public buildings or multi-story dwellings, even in humid climates. Most regions require certifications like ASTM E84, NFPA 285, or EN 13501-1 depending on the jurisdiction. MGO boards often meet or exceed these benchmarks without added treatment.

3. Moisture and Mold Control Mandates

Health regulations often demand that construction materials in coastal environments be resistant to mold and microbial growth. Panels must meet ASTM D3273 for mold resistance or equivalent standards in the EU and Middle East.

4. Corrosion Protection Guidelines

In areas with high salt exposure, some local codes require corrosion-resistant materials not just for cladding, but also for fasteners, support systems, and framing elements. These include hot-dip galvanized, stainless steel, or epoxy-coated components.

5. LEED and Green Building Certifications

Sustainable coastal development often involves meeting LEED, Estidama, or BREEAM guidelines. Choosing VOC-free, recyclable, and non-toxic wall panel materials contributes to certification points and long-term environmental compliance.

6. Documentation and Product Testing Reports

Contractors and developers must retain certificates of compliance, third-party testing reports, and safety data sheets for any wall panel system used in regulated coastal zones. This documentation is essential for passing inspections and ensuring future liability protection.

Adhering to these coastal building regulations ensures that selected wall panels for coastal buildings are not only high-performing but also legally compliant and insurable—laying the foundation for safe, enduring structures.

Real-World Case Studies of Coastal Wall Panel Use

Seeing how wall panels for coastal buildings perform in actual projects helps validate their durability and effectiveness. In this section, we highlight several successful implementations of advanced wall panel systems—especially MGO boards—in diverse coastal environments across the globe.

Luxury Beachfront Resort – Ras Al Khaimah, UAE

Challenge: High humidity, salt spray from the Persian Gulf, and intense UV exposure.

Solution: MGO boards were used for all internal partition walls and utility spaces.

Result: Zero mold growth over five years, excellent indoor air quality, and no warping despite daily exposure to humidity.

Coastal Health Center – Da Nang, Vietnam

Challenge: Tropical monsoon climate with heavy rainfall and biological risks.

Solution: Fire-rated MGO boards installed in emergency rooms and corridors.

Result: Passed all health safety inspections. Facility received LEED Silver certification due to use of eco-friendly, low-VOC materials.

Government Administration Building – New Orleans, USA

Challenge: Compliance with strict hurricane codes and flood zone construction.

Solution: A combination of fiber cement panels and MGO interior partitions.

Result: The building met Florida Building Code standards and remained operational after two major storm events.

Residential Coastal Villas – Southern Italy

Challenge: Salt corrosion, long sunlight exposure, and aesthetic preservation.

Solution: Aluminum composite panels were used externally, and moisture-resistant gypsum boards internally.

Result: Smooth, modern appearance with minimal maintenance required over 8 years.

These case studies show that with the right material selection and design strategy, wall panels for coastal buildings can deliver exceptional performance even under the harshest conditions.

Cost Considerations & ROI for Coastal Wall Panels

Cost is a decisive factor in any construction project—but when it comes to wall panels for coastal buildings, the cheapest solution upfront may lead to costly problems later. Here, we break down the financial implications of different wall panel choices and examine their return on investment (ROI) in humid, salt-heavy environments.

1. Initial Material Cost

| Material | Approximate Price (USD/m²) |

|---|---|

| MGO Board | $10–$14 |

| Fiber Cement Board | $9–$12 |

| Aluminum Composite | $12–$18 |

| Vinyl/PVC Cladding | $5–$8 |

| Stainless Steel Panels | $20–$30 |

MGO offers premium performance at a mid-range price point—an ideal balance for coastal use.

2. Installation Costs

Some panels (like MGO or fiber cement) may have slightly higher labor costs due to specialized handling or cutting. However, these costs are often offset by faster project completion and reduced rework.

3. Long-Term Maintenance Expenses

Cheap panels like PVC may require frequent repainting, re-sealing, or full replacement within 10–15 years. High-quality options like MGO require minimal upkeep and often come with 30-year warranties, saving thousands in repairs over time.

4. Risk Mitigation

Failing to use moisture- and salt-resistant materials in coastal projects can lead to:

- Structural deterioration

- Indoor mold issues (especially in hospitals/schools)

- Fines or penalties for non-compliance

- Increased insurance premiums or claims denial

Choosing certified wall panels early on protects not only the structure but also your legal and financial interests.

5. Return on Investment (ROI)

Over a 20-year building lifecycle:

- MGO boards typically yield 25–40% savings in total lifecycle costs compared to standard gypsum or vinyl siding.

- Projects using compliant wall panels also tend to receive faster approvals and qualify for green building incentives.

Choosing the right wall panels for coastal buildings isn’t just a construction decision—it’s a strategic investment in resilience, efficiency, and long-term value.

Mistakes to Avoid When Selecting Wall Panels for Coastal Buildings

Choosing wall panels for coastal buildings requires careful consideration. Unfortunately, many projects suffer from avoidable issues due to misjudgments in material selection, installation, or budgeting. In this section, we’ll highlight the most common mistakes and how to avoid them in coastal construction.

1. Prioritizing Cost Over Performance

While it’s tempting to choose cheaper materials like PVC cladding, these panels often fail under coastal conditions—leading to moisture damage, corrosion, and higher long-term costs.

✅ What to do instead: Evaluate total cost of ownership (TCO), not just upfront pricing.

2. Ignoring Salt and Moisture Resistance Ratings

Some manufacturers don’t clearly label their products’ performance against salt or humidity. Without verified specs, you risk using materials that degrade rapidly.

✅ What to do instead: Choose panels that are third-party tested and compliant with international moisture and corrosion standards.

3. Using Incompatible Fasteners or Substructures

Even if your wall panels are high-quality, pairing them with standard steel fasteners can introduce rust and weaken the system.

✅ What to do instead: Always use corrosion-resistant screws, anchors, and furring systems suitable for marine environments.

4. Poor Sealant or Joint Application

Unsealed gaps allow water and salt into the building envelope. This is one of the most common causes of mold and internal panel damage.

✅ What to do instead: Use elastomeric, UV-resistant sealants and reapply them during routine maintenance.

5. Disregarding Local Codes and Certifications

Each coastal region may have unique codes governing materials, wind resistance, and fire safety. Skipping these can delay approvals or fail inspections.

✅ What to do instead: Check compliance with regional standards (e.g., FBC, ASTM, EN, UAE Fire Code).

6. Underestimating Aesthetic Degradation

Salt, wind, and UV rays can fade or stain certain finishes. Some panels may look new for just a few years.

✅ What to do instead: Choose coatings and finishes specifically rated for UV and salt exposure, with manufacturer warranties.

Avoiding these mistakes ensures that your wall panels for coastal buildings perform reliably, reduce maintenance costs, and meet all regulatory expectations—while preserving the architectural integrity of the structure.

Conclusion – Building Resilient Structures for Coastal Living

In coastal construction, aesthetics and performance must go hand in hand. The unforgiving environment—marked by constant humidity, salt-laden winds, UV radiation, and regulatory scrutiny—demands more than just ordinary materials. It demands well-researched, high-performance wall panels for coastal buildings.

Magnesium oxide (MGO) boards, fiber cement panels, and other advanced solutions have proven themselves as durable, code-compliant, and aesthetically flexible materials. Whether you’re designing a luxury villa by the sea, a commercial structure near the coast, or a public building in a tropical zone, investing in the right wall panel systems ensures:

- Long-term structural integrity

- Minimal maintenance burden

- Healthier indoor air quality

- Better resistance to climate challenges

- Increased property value and ROI

As coastal cities continue to grow—and climate conditions become more volatile—choosing the right wall panels is not just a design choice; it’s a commitment to sustainability, safety, and long-term peace of mind.

Ready to Build Stronger by the Shore?

Choosing the right wall panels for coastal buildings can mean the difference between frequent repairs and long-term resilience. At MaxBoard, we specialize in high-performance MGO panels engineered specifically for the toughest environments—from salty coastal air to humid tropical zones.

💡 Looking for tested and trusted panels for your next project?

Explore our full product line and technical resources now:

Build better. Build with confidence. Build with MaxBoard.

Frequently Asked Questions(FAQ) about wall panels for coastal buildings

What are the best materials for wall panels for coastal buildings?

The best materials for wall panels for coastal buildings include magnesium oxide (MGO) boards, fiber cement panels, and aluminum composite panels. These materials resist salt corrosion, moisture penetration, and UV damage, making them ideal for harsh coastal environments.

Why are wall panels for coastal buildings different from those used inland?

Wall panels for coastal buildings are specifically engineered to handle high humidity, salt-laden air, and rapid temperature shifts. Inland panels may lack the necessary resistance, which can lead to faster degradation, mold growth, and higher maintenance costs in coastal conditions.

Are MGO boards a reliable choice for wall panels for coastal buildings?

Yes, MGO boards are among the most reliable options for wall panels for coastal buildings. They are fire-resistant, water-resistant, mold-resistant, and offer excellent structural stability. MGO panels also maintain their appearance and integrity under extreme weather conditions.

How often should wall panels for coastal buildings be maintained?

Maintenance schedules for wall panels for coastal buildings vary by material, but high-quality options like MGO boards require minimal upkeep—usually a visual inspection and resealing of joints every few years. Lower-grade panels like PVC may need more frequent repainting or replacement.

Can wall panels for coastal buildings improve energy efficiency?

Absolutely. Many wall panels for coastal buildings are designed with insulation layers that reduce thermal transfer, helping to keep interiors cool in hot, humid coastal regions. This improves HVAC efficiency and reduces energy costs.

Do building codes require specific wall panels for coastal buildings?

In many regions, building codes mandate the use of certified and tested wall panels for coastal buildings. Panels must meet standards for moisture resistance, fire safety, and wind load performance, especially in hurricane-prone coastal zones.

Where can I buy high-quality wall panels for coastal buildings?

You can purchase certified, high-performance wall panels for coastal buildings directly from MaxBoard-MGO.com. Our MGO panels are trusted by builders across tropical and marine climates for their durability, safety, and compliance with global standards.